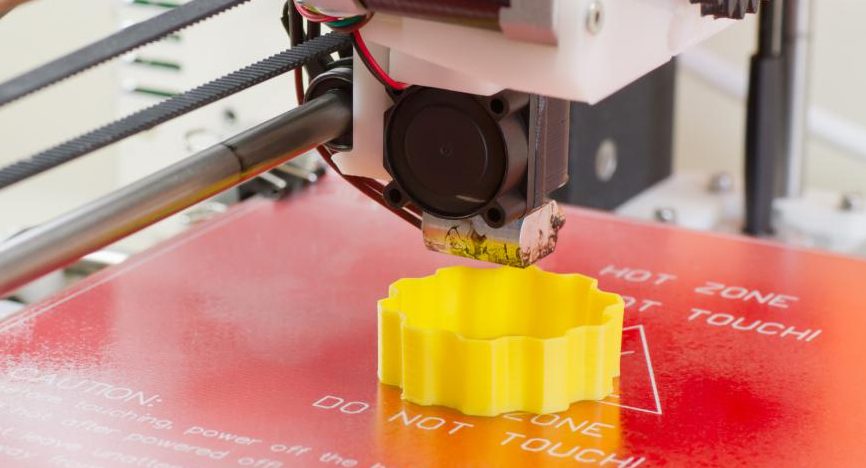

One of the biggest hurdles the additive manufacturing industry (more commonly known as “3-D printing”) faces is the by-product of combustible dust. It’s critical to clearly identify the specific hazard that applies to the kind of dust you are working with. According to a 2008 study by the Combustible Dust Policy Institute, metal and plastics combined for nearly 40% of the 200+ combustible dust-related fires and explosions in all major sectors during that year, proving that many are either unaware or ignoring the dangers their materials pose.

Many combustible dusts can easily be vacuumed with an explosion-proof certified vacuum cleaner. However, there is a definitive difference on what type you use depending on the application are containing. Plastic dusts, while equally dangerous as metal dusts, require a more traditional vacuum system. So which vacuum should you use for plastic additive manufacturing dust? These are the key features to look for…

- An explosion proof dry vacuum

- One that has been legally ETL Certified to UL and CSA standards for Class I, Div 1, 2, Group D and Class II, Div 1, 2, Group F & G atmospheres

- Continuous duty motor operation to meet the demands of an industrial workflow

- Carbon impregnated housing that is chemically neutral and static dissipating to eliminate static discharge

- Rugged and dent-free to withstand the wear and tear of being operated in an industrial environment

- Promotes a high CFM rate capable of easily removing small, fine dust

- Contains HEPA filtration to ensure that lead particulates don’t saturate the atmosphere, leading to the increased risk of lead exposure to you and your employees

Making sure your workers are aware of the dangers of combustible dust and implementing a housekeeping program on the work floor are also paramount to safeguarding your additive manufacturing facility. By following these guidelines for selecting an industrial vacuum for plastic additive manufacturing, you can significantly decrease the chance of having a dangerous accident as well as keep your workspace dust-free.