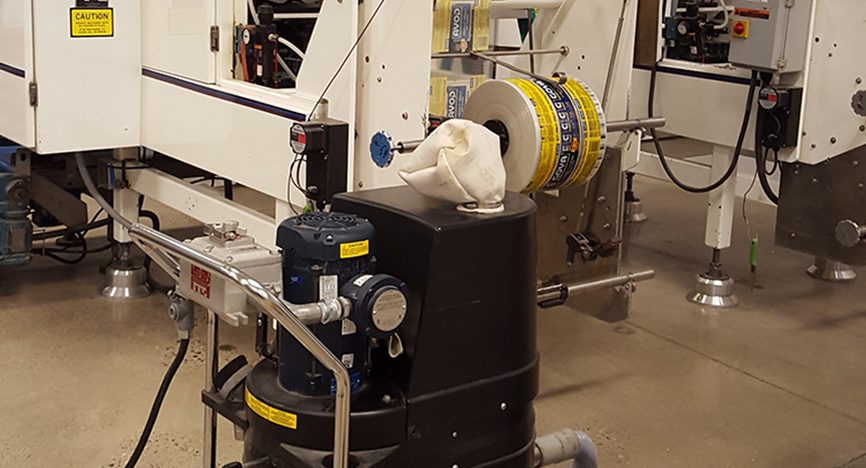

Process manufacturing extends into a diversity of industries, from nutraceuticals and pharmaceuticals to plastics, stamping, cosmetics and food packaging. Often, fine dust and particles are left behind as a by-product which makes the commonality between them being a housekeeping nuisance or potential waste of product. Cross-contamination worries without the use of specialized equipment prohibits the collection of the dust for reuse, and ultimately, this translates to the manufacturer’s bottom line being spread thinner than it should be. Your solution to these problems lies within finding the right industrial vacuum system intended to safely and efficiently clean these particular applications. So which vacuum should you use for processing point of extraction? Here’s some of the major features to look for…

• An extremely portable, compact low profile design that fits any setting and is highly accessible

• A vacuum that provides 24/7 continuous duty operation will increase productivity while on the processing line

• Point of source extraction that provides a high CFM rating to ensure fine dusts are easily removed

• A vacuum that keeps workspace sanitary and clean by collecting dust particles for reuse without cross-contamination. A metal container will be your best bet.

• If working with food dust, a stainless steel container alongside food-grade accessories are necessary to comply with FDA regulations for particle handling

• Vacuum systems featuring a solid all-metal container construction will also enhance the durability and longevity of its life

• Ample filtration and optional HEPA for air purification

• Quiet operation so as not to exasperate noise conditions on the work floor

• Easy emptying, such as quick removal latches on its lid for fast dumping or recycling disposal

In short, you should be looking for an industrial vacuum system that won’t compromise the manufacturing process while eliminating fine dust and particles out of the equation. What material exactly you are extracting alongside the size of your production should also be taken into consideration. In using this information, hopefully you will be able to make the right decision in choosing a vacuum for processing point of source extraction. If you any have any questions, helpful tips or suggestions, let us know in the comments section below!