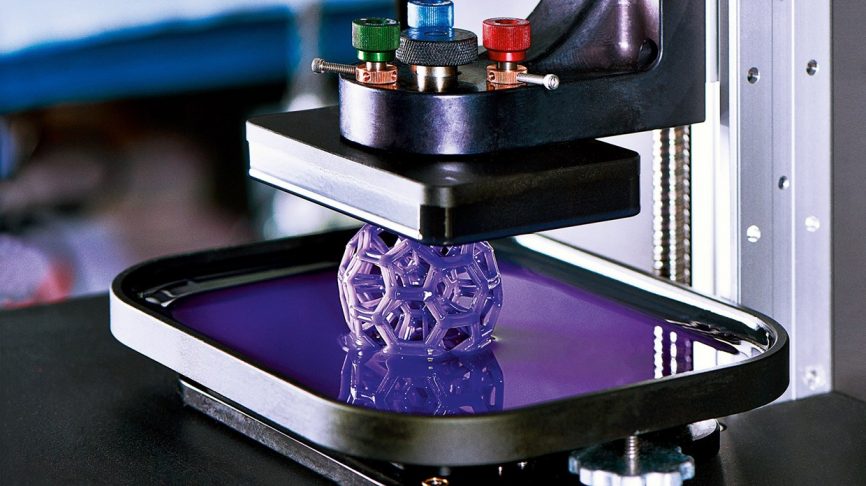

Additive manufacturing is one of the most rapidly growing and evolving markets happening in the industrial world right now. It’s cost-effective in terms of materials and productivity, and in many cases, it provides a greener solution that leaves less of a carbon footprint on the environment. It used to be that just those working with metals and plastics were taking advantage of this new technology, but each day, more and more industries — from food production to biomedical breakthroughs— are finding a innovative way to integrate 3D printing into their work.

With that comes new hurdles in safety, especially when it comes to the byproduct of dust these processes can create. The compositions of the materials are becoming more exotic and changing rapidly, and it becomes critical to clearly identify the specific hazard that applies to the kind of dust you are working with. According to a 2008 study by the Combustible Dust Policy Institute, metal and plastics alone combined for nearly 40% of the 200+ combustible dust-related fires and explosions in all major sectors during that year, proving that many are either unaware or ignoring the dangers their materials pose.

For those particular manufacturers, choosing the right explosion proof vacuum cleaner for safe dust collection becomes paramount, but you can imagine that a day will come where the need for industrial vacuums that remove dust from additive manufacturing sites will go beyond just combustible dust safety. For instance, there’s the rise of digital construction, seen in stories of how the U.S. Army is using it to build cement barracks, or how one firm in Singapore has created a new geopolymer cement made from waste fly ash particles, a byproduct from coal combustion processes that can be recycled in bricks and foundation. While the latter article goes on to say that “The future of construction is most likely to be an integrated process that allows organizations to take advantage of both conventional and additive manufacturing technologies at the same time,” one must wonder how inviting additive manufacturing technology into the equation may create new dust dilemmas for construction workers that are already up against hazardous concrete and silica dust.

If that day ever does come, the best thing industries across the board can do is to always understand the nature of their dust before it becomes a problem. This involves educating yourself and training all workers on your respective application, and any possible dangers it may present. If you need guidance, Ruwac USA is always here to help. Our team of experts will work with you to ensure that your industrial vacuum solution meets all safety requirements as well as provides the most cost-effective solution to your dust removal needs.