Overview

Venturi Air Powered – Immersion Separation System

- two 150 CFM options available

- rated Class I, Div 1 – Group D and Class II, Div 1 – Groups E, F, and G environments

- continuous duty operation – run 24/7

- portable and compact with increased performance and technologies

- multi-user functionality (run multiple operators for certain applications)

- safely collect and neutralize aluminum, titanium, magnesium, zirconium, mixed metals, sodium azides, TNT, high explosives and other volatile dusts

- venturi systems creates very high vacuum

Vacuum Classifications:

- Class I, Div 1 – Group D and Class II, Div 1 – Groups E, F, and G environments

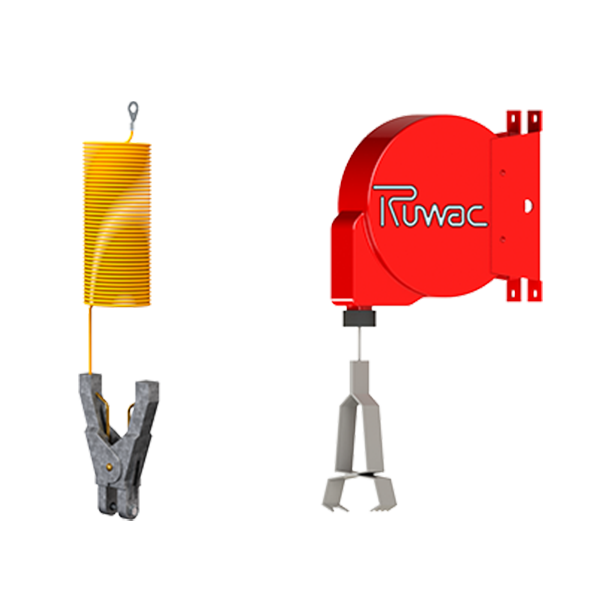

NFPA 484 Requires Independent Grounding:

*New NFPA 484 Compliance Standards require that all wet mix immersion vacuum systems have an independent ground from the facilities electrical system. See Ruwac’s solution!

Industries and Applications:

• Additive manufacturing

• Automotive vehicle part manufacturers

• Air bag manufacturers

• Aviation part manufacturers

• Aluminum

• Magnesium

• Titanium

• Zirconium

• Conductive metals and Group E dusts

• Gun powder manufacturers

• Impact sensitive materials

• 3D Printing

• Laser Sintering

• Fine Metal Powders

Specifications

*Specs subject to change without notice

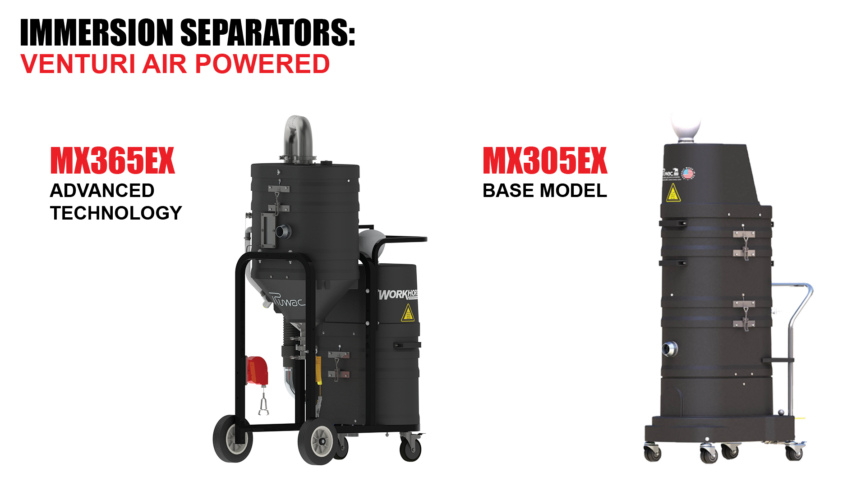

MX365EX MORE INFO

| Motor Rating: | Power: | Minimum Required CFM: | CFM: | H20": | Filter Size: | Capacity: |

|---|---|---|---|---|---|---|

| Stainless Steel Air Venturi | Air Powered | 65 CFM minimum | 150 CFM | 136" H20 | 44 sq. ft. hydrophobic | 12 Gallons |

MX305EX

| Motor Rating: | Power: | Minimum Required CFM: | CFM: | H20": | Filter Size: | Capacity: |

|---|---|---|---|---|---|---|

| Stainless Steel Air Venturi | Air Powered | 65 CFM minimum | 150 CFM | 135" H20 | 44 sq. ft. hydrophobic | 9 Gallons |

Features and Benefits

Technology and Benefits:

With 100% of intake air being completely submerged and neutralized in the immersion separation “liquid bath”, the chance of an outside ignition source entering the wet mixer vacuum is safely ruled out. Utilizing a liquid-based filter system, the MX365EX Series vacuum will safely collect and neutralize aluminum, titanium, magnesium, zirconium, mixed metals, sodium azides, TNT, high explosives and other volatile dusts.

- ETL certified to UL and CSA standards

- Motor and switch certified for Class I, Divisions 1 and 2 Group D and Class II, Divisions 1 and 2 Groups E, F and G combustible dust

- NFPA 484 Compliant

-

Designed to safely collect conductive metals, explosive or impact sensitive materials or glowing media

- Available in continuous duty TEFC motor or air-powered single venturi

- Equipped with sound suppression for quiet operation

-

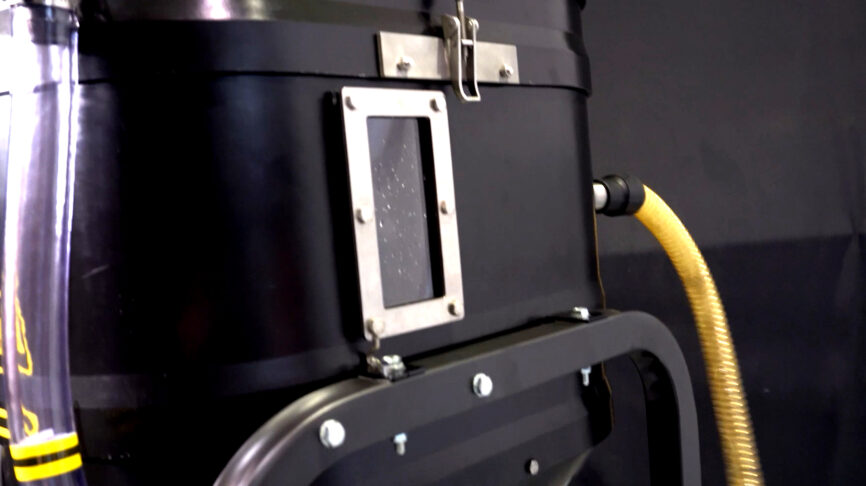

Durable compression cast “bulletproof” composite housing will never dent or rust — Guaranteed for life!

- Hydrophobic filters provide superior sub-micron filtration

- Ergonomically-friendly stainless steel ball valve with sanitary discharge fitting easily relieves sludge and debris build up from inside the vacuum

- Counterbalanced heavy duty casters and two-stack design provide maximum portability

- Low maintenance design with easy access to filters, dispersion screen and demisting pad

- Includes grounding reel for NFPA compliance

- Optional HEPA Maxx or ULPA filter upgrades for absolute filtration

Options

*Specs subject to change without notice